Production Lines

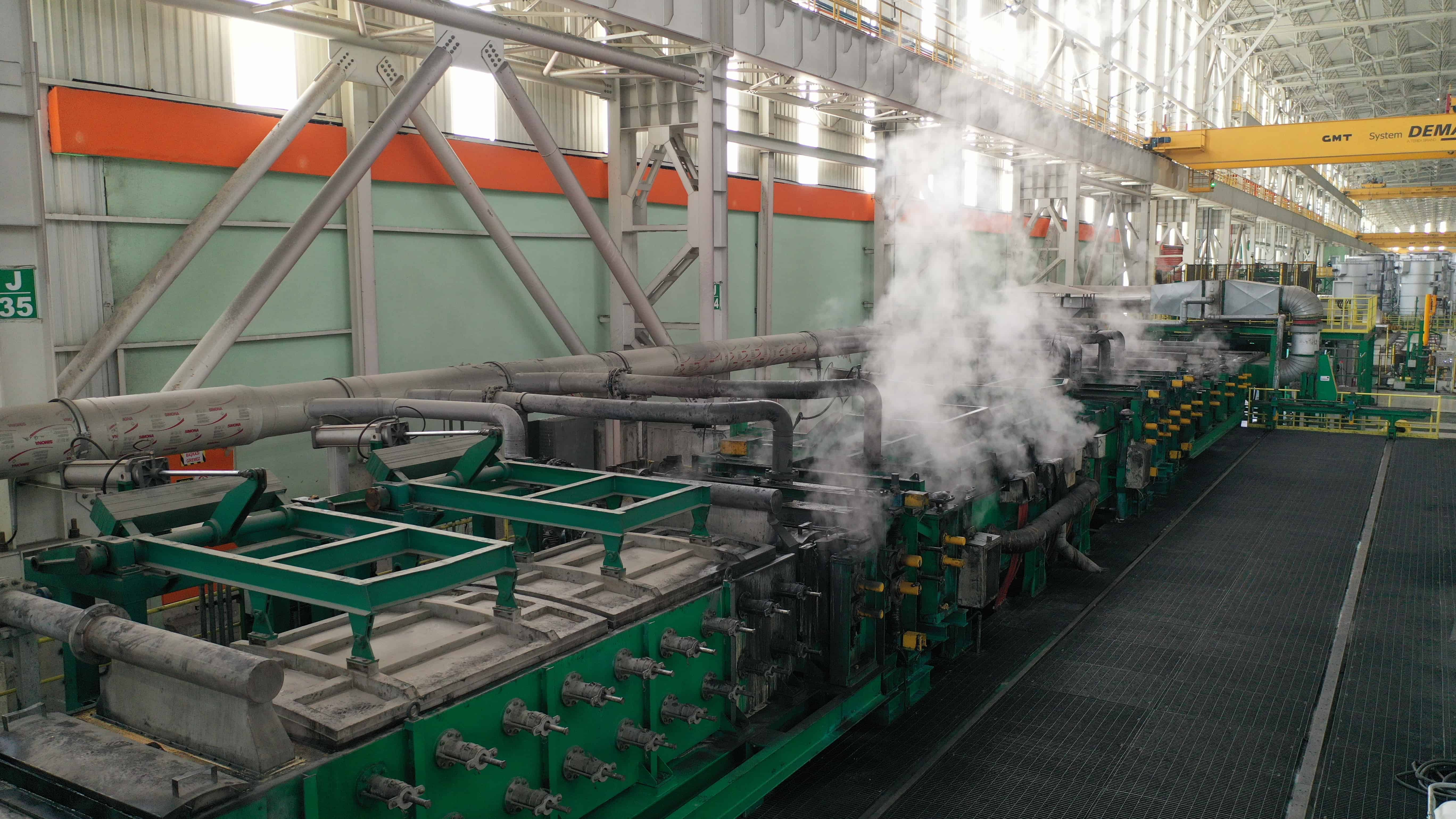

PLTCM (Pickling Line and Tandem Cold Mill) CGL (Continuous Galvanizing Line) CCL (Painting Line) CAL (Continuous Annealing Line) ECL (Electrolytic Cleaning Line) BAF (Batch Annealing Furnace) Line (Tempering And Double Cold Reduction) ETL (Electrolytic Tinning Line)The Electrolytic Cleaning Line is utilized to remove the rolling oil and iron powder from the surface of the full hard coils retrieved from the TCM unit prior to the BAF (Batch Annealing Furnace).

The coils arrive at the plant, where the end of the former and tip of the new coils are welded. This process is followed by rinsing and drying after cleaning by chemical, electrolytic and mechanic cleaning (brushing) to reproduce a coil.

| About the ECL Features | |

| Founding Company | Tenova-TSP |

| Annual Production Capacity | 192.000 ton/yıl |

| Coil Weight (average) | 18 ton |

| Strip Width (min-max) | 700 – 1300 mm |

| Strip Thickness (min-max) | 0,16-1,6 mm |

| Input Coil Diameter | 1000-2250 mm |

| Output Coil Diameter |

100 mpm |

| Process Speed | 450 mpm |

| Steel Grade | CR Full Hard, Black Plate for tinning |